Machine tool fixtures, this seemingly obscure industrial component, are actually an invisible yardstick for measuring a country's high-end manufacturing capabilities. At the EMO exhibition in Stuttgart, Germany, a five axis linkage machining center equipped with intelligent fixtures is demonstrating flexible machining of titanium alloy aviation components. The fixture system adjusts the parameters of the clamping force in real-time on the operation panel, attracting global buyers to stop and watch. At the Shanghai International Machine Tool Show held at the same time, a leading domestic enterprise showcased hydraulic combination fixtures that were praised as "domestic masterpieces". However, the booth manager privately admitted, "When processing aircraft engine blades, we still need to import German fixtures to ensure positional tolerances." This subtle contrast reflects the transformation and pain that China's machine tool fixture industry is experiencing.

1、Precision Gap: The Technical Barrier Behind 0.005mm

At a private mold factory in Taizhou, Zhejiang, Li Ming, the technical director, shook his head at the 0.02mm parallelism error on the inspection report and said, "The German fixture can be stably controlled within 0.005mm, and this gap directly leads to a 15% decrease in the qualification rate of our automotive cover mold production." This seems to be a small precision gap, originating from the deep accumulation of materials science. The fixture substrate of ROEMHELD, a century old German enterprise, is made of self-developed ductile iron. Its microstructure stability is three orders of magnitude higher than that of domestic HT300 gray cast iron, and the deformation can be controlled within 1 μ m/℃ under temperature changes.

More importantly, there are intergenerational differences in sensing technology. The intelligent fixture of Fengxing Manufacturing Co., Ltd. in Japan has integrated a strain gauge array and a temperature compensation module, which can sense changes in cutting force in real time and automatically adjust the clamping strategy. However, most domestic enterprises still use mechanical limit devices, which can easily cause workpiece displacement when processing parameters suddenly change. The technical director of a certain military enterprise revealed that "during the processing of certain missile servo components, the waste loss caused by the dynamic response lag of fixtures exceeds 8 million yuan per year

2、Market Pattern: The Interweaving Dilemma of Low end Red Sea and High end Monopoly

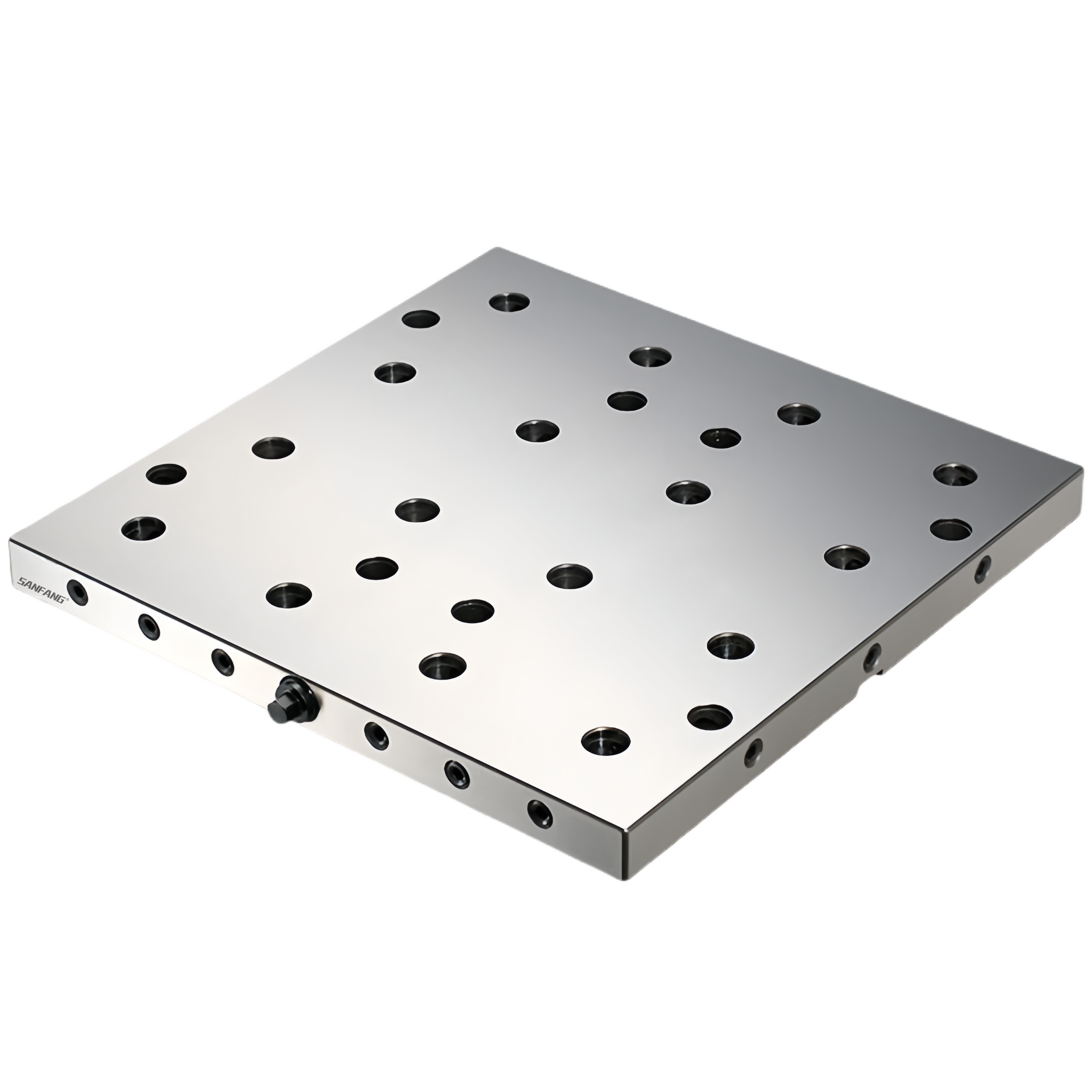

According to the 2023 Industry White Paper of the China Machine Tool and Fixture Association, among the more than 2000 related enterprises in China, less than 30 have an annual output value of over 100 million yuan, and 90% of the enterprises are concentrated in the mid to low end fields such as combination fixtures and universal flat pliers. In sharp contrast, five major foreign brands such as SCHUNK from Germany and REGO-FIX from Switzerland monopolize 85% of the domestic market share for high-end machine tool fixtures, with a market share of over 95% in key areas such as automotive powertrains and aviation structural components.

This structural contradiction is particularly prominent in the manufacturing cluster of the Yangtze River Delta. A supplier of a CNC machining center in Suzhou admitted that "customers specify the use of German fixtures, otherwise the equipment quotation will be reduced by 20%." What is even more alarming is that foreign-funded enterprises are deepening their moat through the ecological binding of "technology+service". The "Fixture Cloud Diagnostic System" launched by HAIMER in Germany can remotely monitor the status of global customer fixtures and provide preventive maintenance recommendations. This industrial service brings customer stickiness far beyond simple product sales.

3、The Road to Breakthrough: Paradigm Shift from Reverse Engineering to Positive Innovation

The recent breakthrough of a private fixture enterprise in Wuxi may indicate the direction. The self-developed magnetorheological flexible fixture system successfully achieves adaptive clamping of complex surfaces in five axis machining by controlling the magnetic field to change the stiffness characteristics of the magnetorheological fluid. This technology has been applied to the manufacturing of a certain type of shipborne radar bracket, reducing the traditional tooling preparation time from 72 hours to 15 minutes. Wang Jianguo, the chief engineer of the enterprise, said, "We started with basic research on material rheology and iterated 17 versions of control algorithms before and after

This transformation is being strengthened at the policy level. The National 04 Special Project has listed "Intelligent Fixture System" as a key research direction, and the "Fixture Industry Innovation Alliance" led by the China Machinery Productivity Promotion Center has integrated the research and development resources of 23 institutes and enterprises. In terms of talent cultivation, Tianjin Vocational and Technical Normal University has pioneered the micro major of "Fixture System Engineer", which integrates modern technologies such as finite element analysis and intelligent sensing into traditional tooling courses. The first batch of graduates has been highly sought after by enterprises.

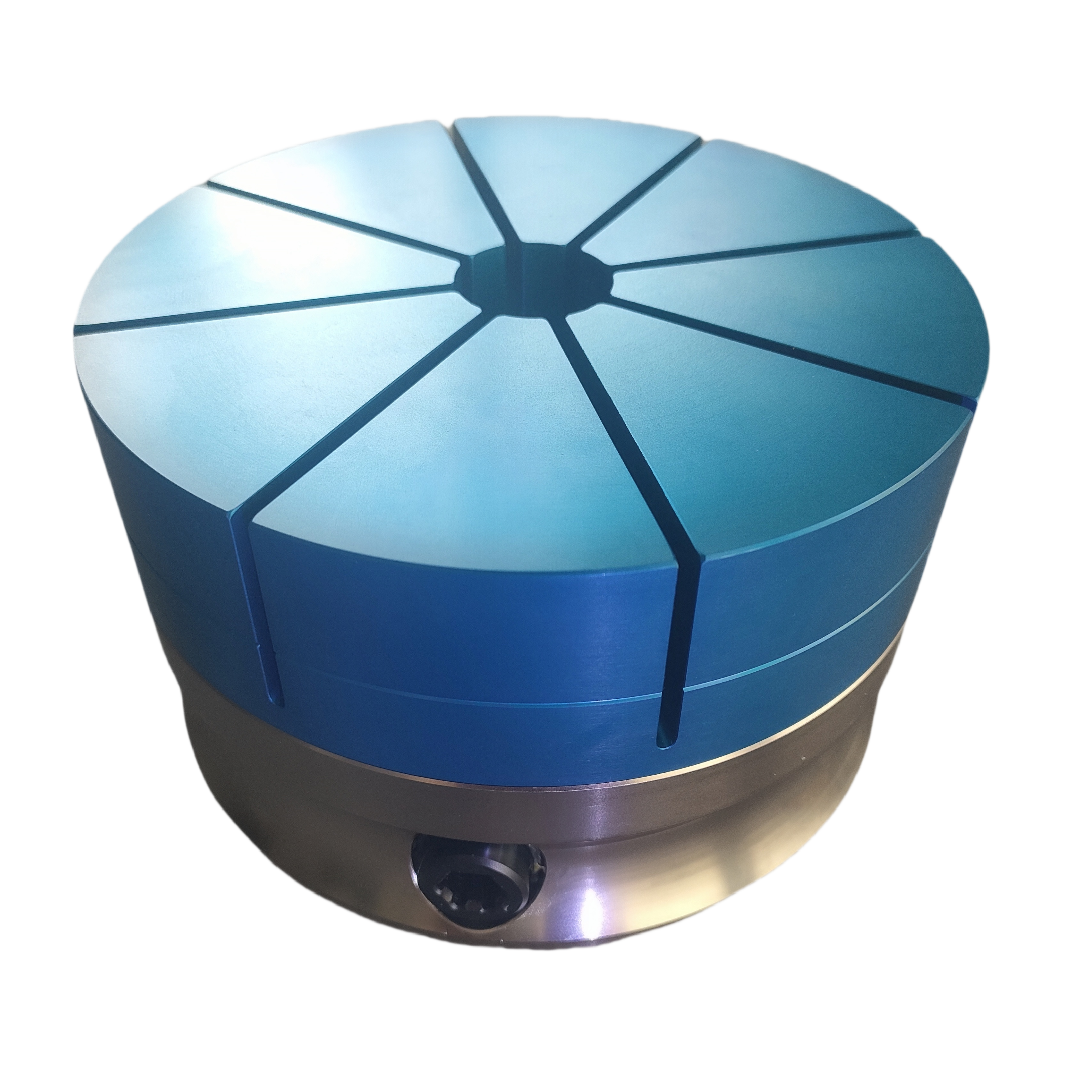

At a smart manufacturing demonstration factory in Qingdao, domestically produced new electric permanent magnet fixtures are showing amazing potential. By combining rare earth permanent magnet materials with pulse magnetization technology, the clamping force per unit area is three times that of traditional fixtures, and the replacement time is reduced by 80%. When German engineers saw that this system successfully fixed a 2-meter diameter wind turbine gearbox planetary carrier for strong milling, they couldn't help but give a thumbs up: "Chinese innovation is redefining the possibility of fixtures

From the splashing of iron filings in precision casting workshops to the virtual debugging of digital twin systems, the upgrading path of China's machine tool and fixture industry is like a high-precision machining center undergoing calibration. When the shortcomings of basic materials, core components, and industrial software are overcome one by one, and when the spirit of craftsmanship and digital intelligence are deeply integrated, this pursuit of manufacturing accuracy will eventually usher in a breakthrough moment for the Chinese solution. After all, in the arena of manufacturing, the tightness of fixtures not only locks in metal workpieces, but also represents a country's determination and wisdom to transition to high-end manufacturing.